Why Tricoya?

Tricoya® creates a new class of MDF products with class 1 durability and exceptional dimensional stability, suitable for a wide range of exterior applications such as door skins and door panels, façade paneling, trim, fascia’s, soffits, etc.

Tricoya® can be cut, machined and installed using techniques and equipment commonly used throughout the building industry and requires low maintenance thereafter. The flexibility of Tricoya® offers endless design opportunities so that it can be cut to size, machined CNC cut, painted, routed, wrapped without impacting its unique properties.

Performance

The functionality and versatility of wood-based composite panels give them universal appeal. Up until this point, the suitability of MDF panels for exterior and indoor constant wet use environments has been limited and over laid with practical limitations.

Tricoya® combines the versatility, ease of machining, ease of coating and large panel format with the performance heritage and credentials of Accoya®. Accoya® and Tricoya® have been in the market since 2007 and 2011 respectively, predominantly in Europe and are living up to the promise for manufacturers and specifiers alike.

Benefits

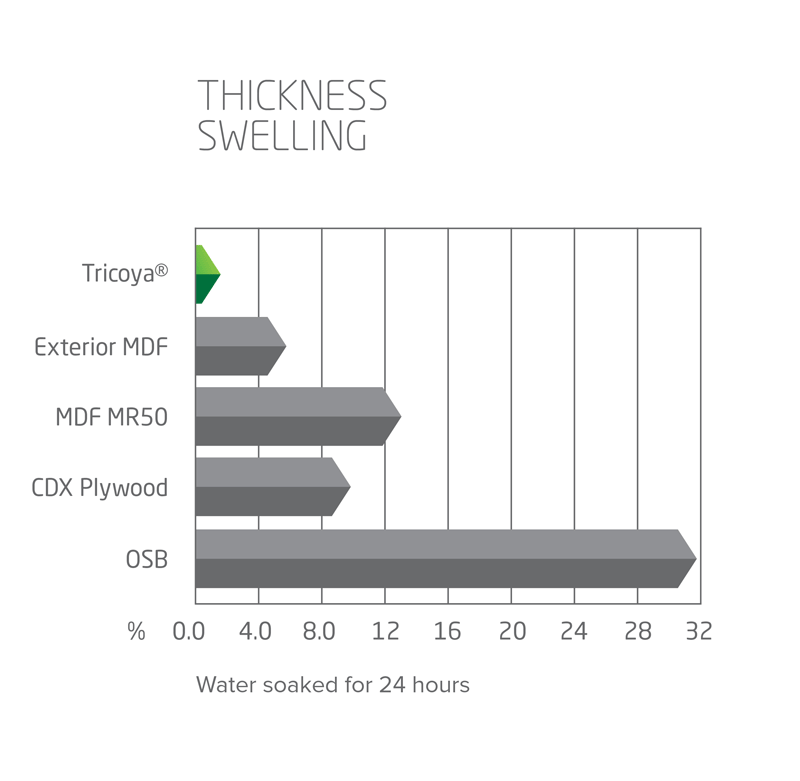

Tricoya is characterised by its durability, dimensional stability and reliability properties. The new design and application possibilities offered by the marriage of acetylated wood fibre with the manufacturing technology of MDF is set to excite and stimulate composite product manufacturers, designers, architects and the construction industry alike, opening up new possibilities and solutions.

- Durable - Longer lasting, perfect for outdoor use or wet (interior) environments

- 50 Years warranty - Peace of mind with a 50 year warranty above ground and 25 years in ground

- Enhanced stability - Swelling and shrinking dramatically reduced

- Design freedom - All the design, fixing and machining flexibility of medium density fibreboards

- Lower maintenance costs - Extended periods between exterior coatings maintenance

- Perfect for coating - Improved stability and durability enhances service life of the coating. Damaged coating will not affect the panel warranty

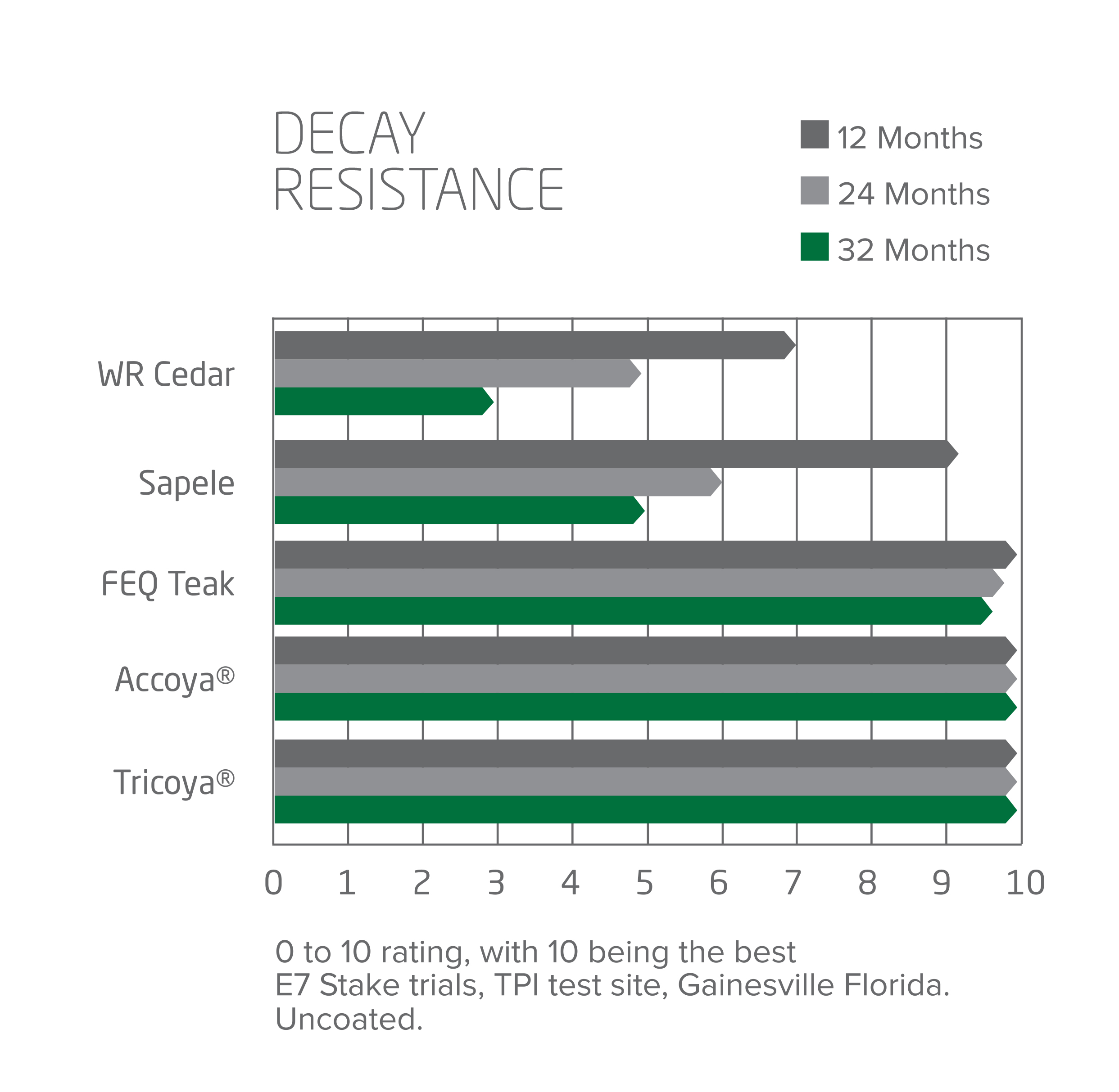

- Resistant to fungal decay - Effective barrier to fungal decay

- Sustainability sourced - Sustainable sourced chain of custody certified

- No added formaldehyde - Tricoya complies with CARB 93120 for Phase 2 and NAF requirements

Applications

The market for Tricoya wood based composites includes, but is by no means limited to:

- Window and door components

- Door skins

Trim - Façade cladding/siding

- Signage

- Fascia/soffit panels and other secondary exterior applications

- Wet interiors, including wall linings in swimming pools, bathrooms, changing rooms, etc.

- Outdoor kitchens

- Specialty furniture including lockers, cubicles, chairs & tables

- Play frames, tree houses & exterior composite furniture

- Sound barriers

Sustainability

All wood used in the Tricoya® production process is sourced from sustainable resources such as certified, reclaimed or recycled timber.